During the colder months, many businesses and construction sites may not think to safeguard against flooding. If you’re part of this majority, you might think hurricane season is the important time to think about flooding. However, according to...

Trust in our 26+ years of water management expertise, you will be in great hands!

During the colder months, many businesses and construction sites may not think to safeguard against flooding. If you’re part of this majority, you might think hurricane season is the important time to think about flooding. However, according to...

Do you know the warning signs of frostbite or hypothermia? Completing construction projects in cold weather can present a number of health concerns for your crew. Make sure your construction site is prepared to handle the cold temperatures this...

Topsoil erosion is one of the biggest environmental issues facing our world today. According to the World Wildlife Federation, half of all topsoil on the planet has eroded away over the past 150 years. And unfortunately, not only is it nearly...

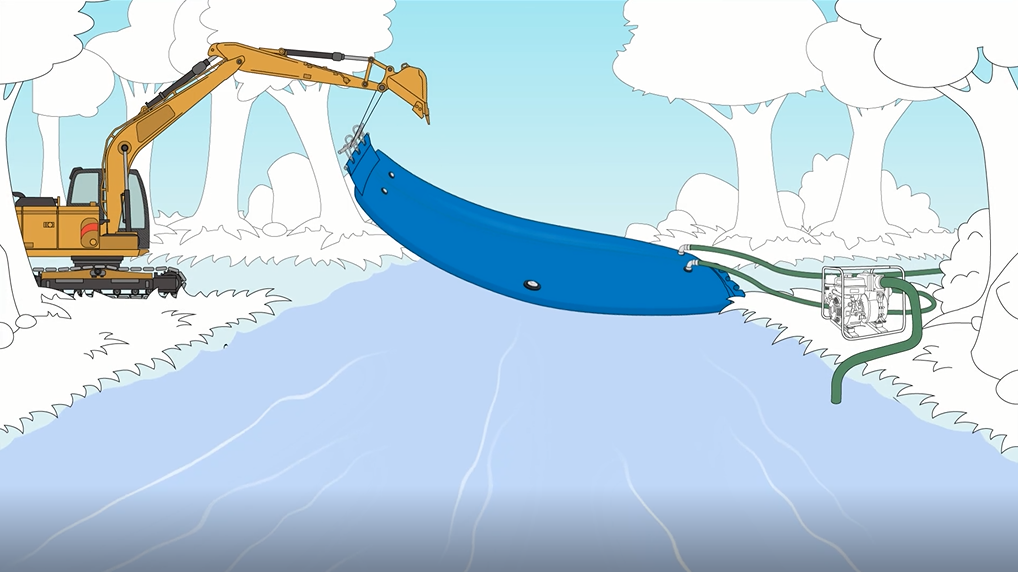

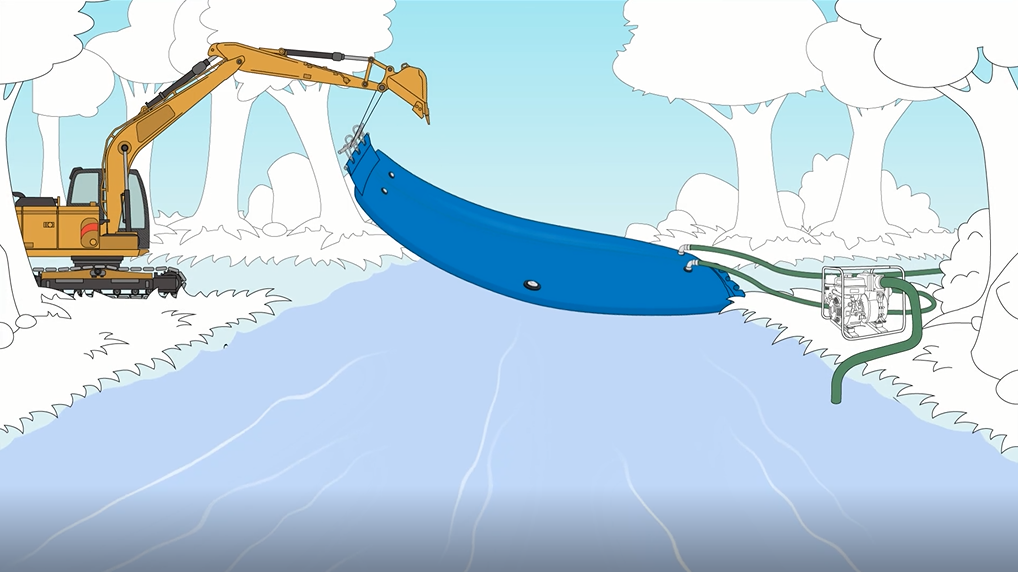

Construction is generally a rather slow-moving job. With a line of crews waiting to work on each section of the project and a looming deadline for completion, it proves to be demanding work. Any way to save time is welcome. Fortunately, jobs that...

Cofferdams are a very effective way to provide dewatering solutions for a number of different projects. They can be utilized for construction sites, shoreline restoration projects, building bridges, and much more. Each project's specifications are...