Water is a powerful force of nature. Without reliable control, water currents can cause extensive damage to buildings, roadways, and equipment. It’s important for businesses, especially construction sites, to have a way to guard against rising...

Trust in our 26+ years of water management expertise, you will be in great hands!

Water is a powerful force of nature. Without reliable control, water currents can cause extensive damage to buildings, roadways, and equipment. It’s important for businesses, especially construction sites, to have a way to guard against rising...

Caissons, cofferdams, inflatable water dams--what are these terms and how do they relate to your construction project? To stay ahead in your construction progress and successfully complete your work, having a dewatering solution is key. Get the...

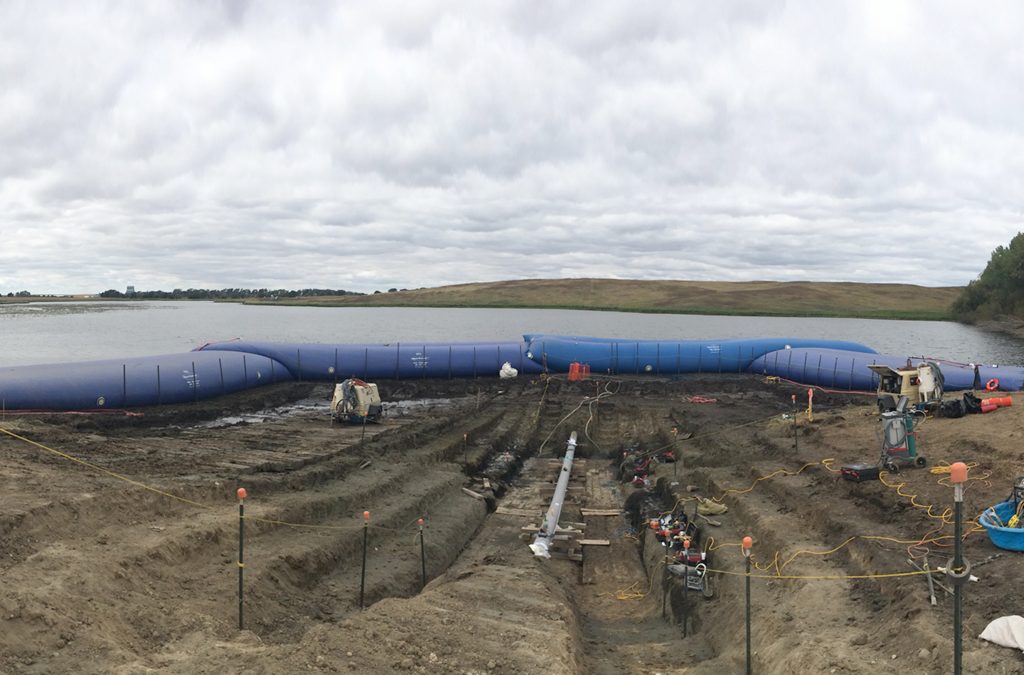

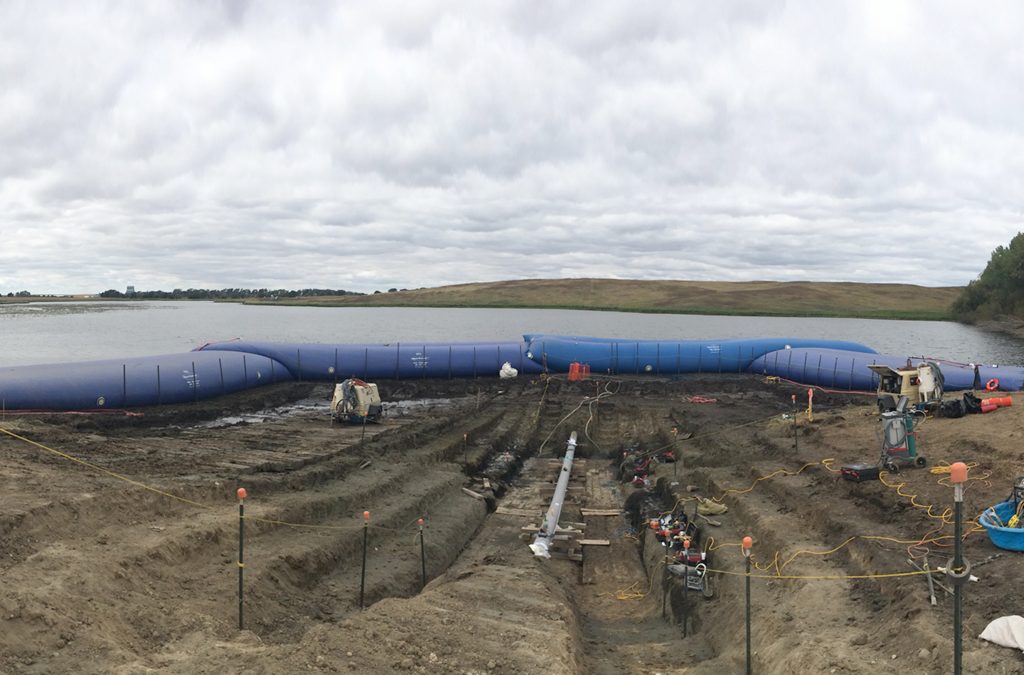

When building a bridge or any other structure in water, a dewatering solution is crucial to completing the project successfully. All dewatering methods are essentially the same, specifically to create a dry work environment. There are, however,...

The new year is a great time to reevaluate your progress and set goals for the future. As you start setting resolutions for 2020, it’s important to think of ways to improve your business and protect your employees. By investing in an Aqua-Barrier...

Do you have the necessary construction equipment for your next project? Does your crew have what they need to work efficiently? With our wide range of water storage solutions and equipment rentals, our construction equipment list is a great way to...

Over 3 million miles of rivers and streams in the United States, and many of these flow into the estimated 84,000 dams around the country. But did you know that not all dams are created equal? They aren’t. In fact, there are many different kinds of...

Operating a construction business costs money, but that doesn’t mean there aren’t ways to cut costs. With careful planning and action, you can also help eliminate waste, decrease negative environmental impact, and boost your bottom line. [bctt...

All building projects need solid plans in order for the construction process to go smoothly. This is especially true for special circumstances, such as dewatering or pipeline construction. [bctt tweet="A carefully planned construction checklist...

The construction industry isn’t slowing down anytime soon, and it has a proven detrimental impact on the environment, too. [bctt tweet="Over 500 million tons of construction debris is discarded per year in America." username="HSIServicesInc"] More...

Finding new ways to cut overhead costs is typically a top priority of many industries, but especially in construction. Over the past few years, construction spending has continually increased, and unfortunately, according to the EPA, much of it...