Trust in America’s Highest Rated, Most Reviewed Cofferdam Supplier

See what people all over the world have to say about their experience with Aqua-Barrier Water Control Solutions & Aqua-Barrier Flood Control Solutions.

The aqua barrier I rented form HSI worked exactly as planned. Maritza set up the right expectations from the beginning and was extremely helpful. Pricing stayed the same and customer service was great. I would highly recommend HSI to any of my colleagues.

Great customer service. This is our only go to when it comes to water diversion.

HSI did a great job working with us and were diligent in providing us exactly what we needed.

Dealing with HSI services makes work a breeze. I have used the aqua bags for years now and they have never let me down. Maritza is always on point when I call in on something I’m not sure about , she always tells me everything I need to know. The questions are never if they can get to me in time only how fast do I need it

The product worked well for our application. Great communication from start to finish. Would use again.

Maritza at Aqua-Barrier was incredibly efficient in providing us a solution and quote to offer our customer. The project went very well.

Very easy to install compared to using sandbags . We will be using this method a lot more in the future to dam off creeks or streams

Great customer service with Jayme. Coordination and shipping was easy and prompt. Provided exactly what we asked for. We'll definitely use Aqua-Barrier again.

Great customer service! Maritza asked all the right questions to ensure we ordered the correct Aqua-Barrier for our pipeline dig-up operation.

The Aqua-barriers work very well. They are easy to install and if done correctly will allow you to work in a creek with no water in the area once pumped out! We plan to purchase more in the future. Highly recommend

Aqua-Barrier was prompt with shipping and coordination with the return of product. Great customer Service. Thanks for your help Jayme!

Aqua Barrier was excellent. Provided what was asked for. They called saying the barrier we wanted was going to be late and offered larger one for no additional cost. Definitely will be working with them again.

The Aqua Barrier product works as described and is very flexible for our job needs. The installation is relatively straight forward and created a buffer between the work zone and the body of water within a day. After seeing the installation process and dewatering efforts afterwards, I believe the aqua barrier saved a significant amount of time on the front end of our projects.

Sebastian flew in to double check us during the installation process, everything went very smooth. He was able to answer any questions we had, we will be using these on future projects as well.

We received the aqua barriers ahead of schedule for delivery which was great ! The staff was excellent at trouble shooting some problems we had on installation and it worked perfect.

Maritza and Brooks have a great deal of knowledge when it comes to the Aqua Bags, I got to deal with them on our project in the Grand Rapids area. We dealt with some extreme issues and the 2 helped us out at all costs, Thanks

I love these bladder bags , they were just as good as I did when I first used them and I continue to use them they are the best thing for creek beds that I’ve ever seen . they are heavy duty and strong and they hold back the water that we need to be held back thank you guys for all your support it’s been a pleasure

Dena and Jayme are professional communicators, very responsive and efficient. Both of my projects have been successful due to the information, instruction, and support of Aqua-Barrier team.

The whole process was easy. From the proposal to delivery and implementation, it was seamless. I would recommend them for your coffer dam needs.

Darren and Kerri have been a pleasure to work with. They have the experiene and expertise to guide customers (and resellers like us) in the right direction. And the products are A1 top-quality.. Durable and dependable. Highly recommend.

We highly recommend HSI Services, Inc. for any and all of your water retention needs. If you have a job site that requires water to be stabilized so that you can perform that work, HSI is your greatest asset and should be your first call. For water retention, a barrier or cofferdam, HSI is available for both technical advice and job solutions.We have called on HSI to assist us with our projects and have always been pleased with the results. They are always available for questions, solutions and followup and that is # 1 in my book when time & money are on the line.Mac McQueen,McQueen Logistics, Inc.

Our experience with HSI was exceptional! The staff is extremely knowledgeable and professional, and the product worked exactly as expected. I would definitely use their services again!

Very accommodating to short schedules and forgiving for not returning it in the best condition. This is the only place we’ll use for our water dig needs!

HSI was great to work with. They were very responsive and helped throughout the process. It also helps when the product performs above expectations. We will be looking to work with them again for sure.

Extremely knowledgeable staff, quality products and industry best customer service. HSI's products and staff met or exceeded our expectations. Very helpful in project design and product selection. Highly recommended and will definitely use them as future needs arise.

Have been working with HSI for numerous years and promoting Aqua-Barrier for many applications in the construction industry.

I have seen the aqua barrier dams working in construction site and controlling floodwaters up to 6 feet they efficient and very eco-friendly and highly reusable a much better alternative to older forms copper dams

You will find HSI to be very professional in every aspect of your dewatering needs. From consultation through the quote process, shipping and onsite services for installation, you will have the best in the industry supporting you all the way through your project. Give them a call and get the best technical support in the industry.

I have personally done business with HSI for 10 years working with my company. They have been an absolute pleasure to work. The team over at HSI has always had our company in their best interests and their customer service has a very family oriented feel to it. Their bladders are our go to source to dewater our construction projects being environmentally friendly and able to support our large construction projects. If you are facing a construction project requiring a dewater scenario, it would behoove you to give HSI a call to get a quote and solution.

Accessories

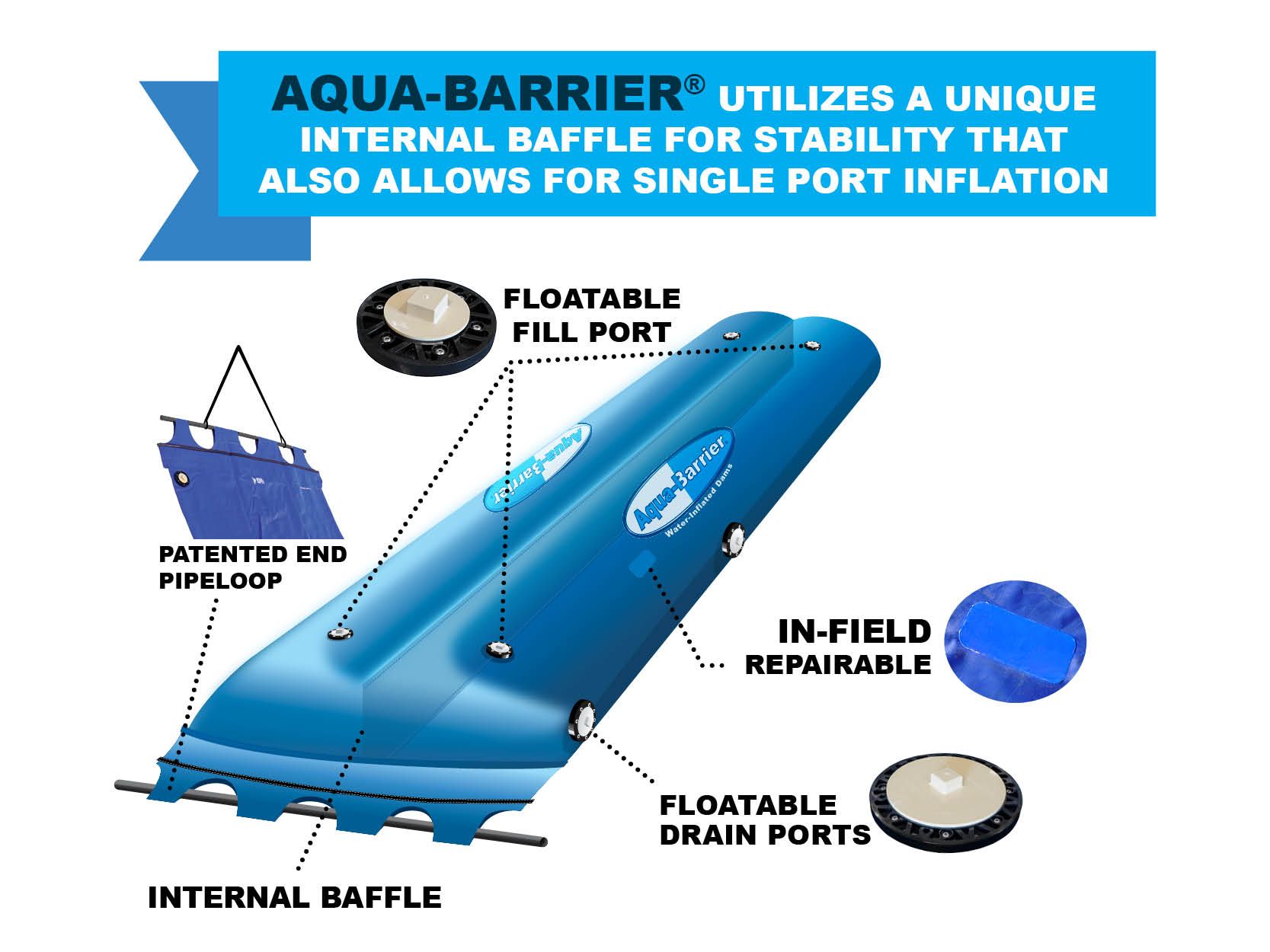

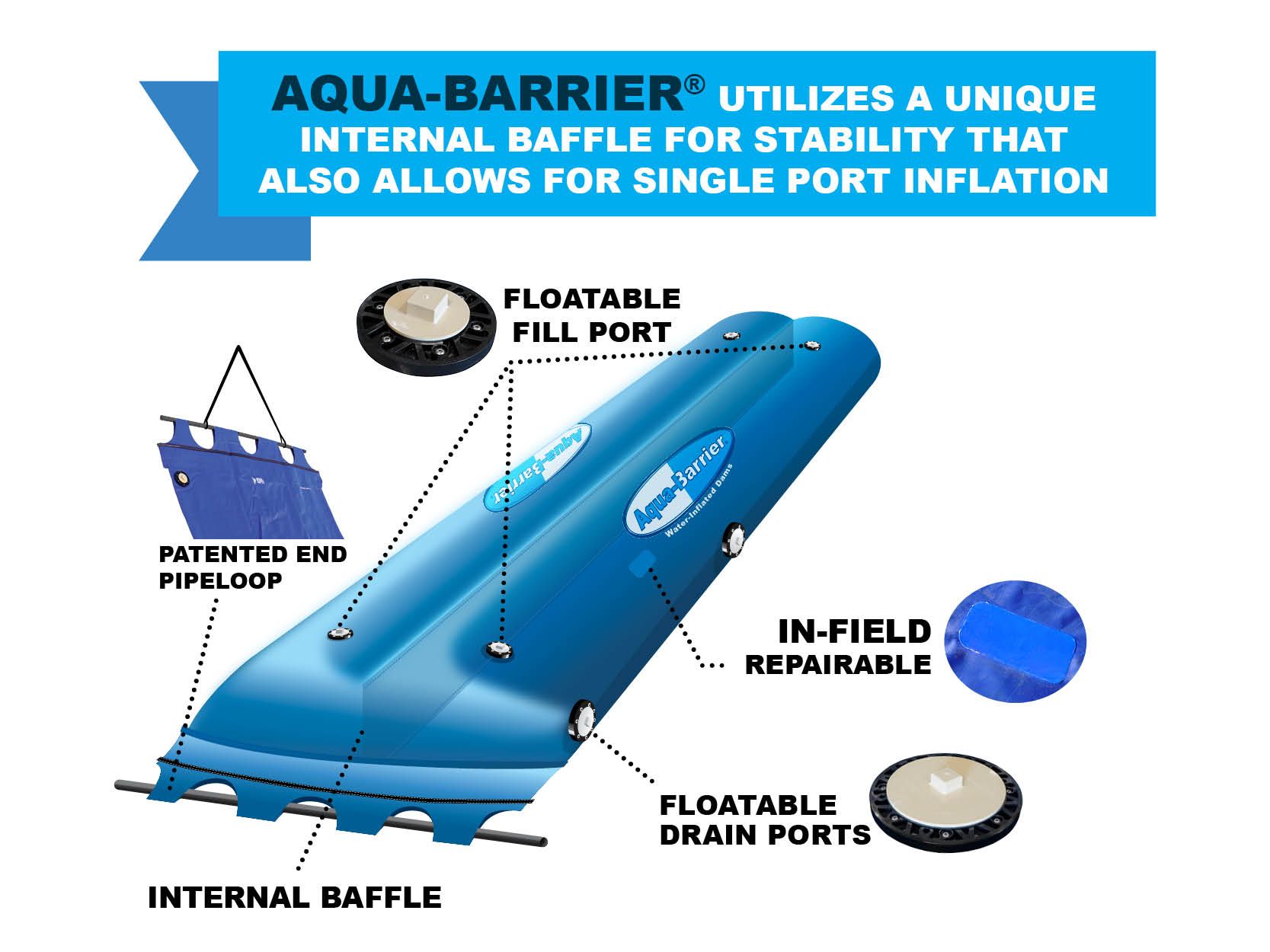

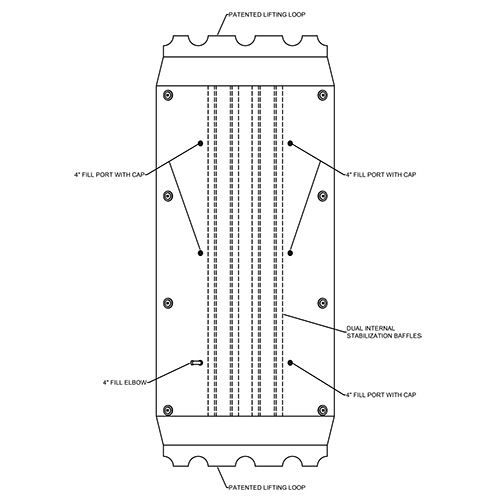

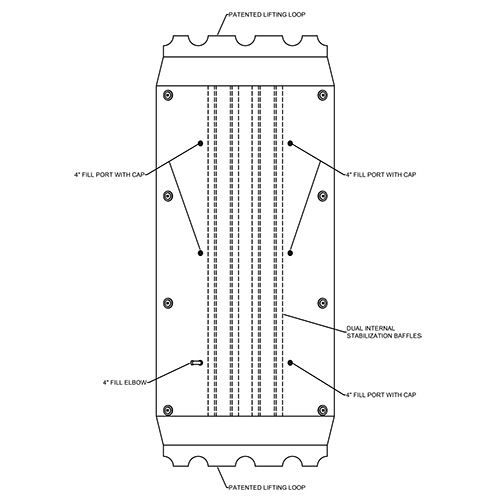

The Aqua-Barrier is engineered with an unique internal baffle system that securely locks into place when exposed to surface friction.

Engineering

Discover how the unique internal baffle system within the Aqua-Barrier has been designed to securely lock in place.

Product Specification

Determine the specific requirements of the Aqua-Barrier to ensure that your application will be successful.

Temporary Water Dams & Cofferdams